Commercial Pilot License (CPL)

Commercial Pilot License

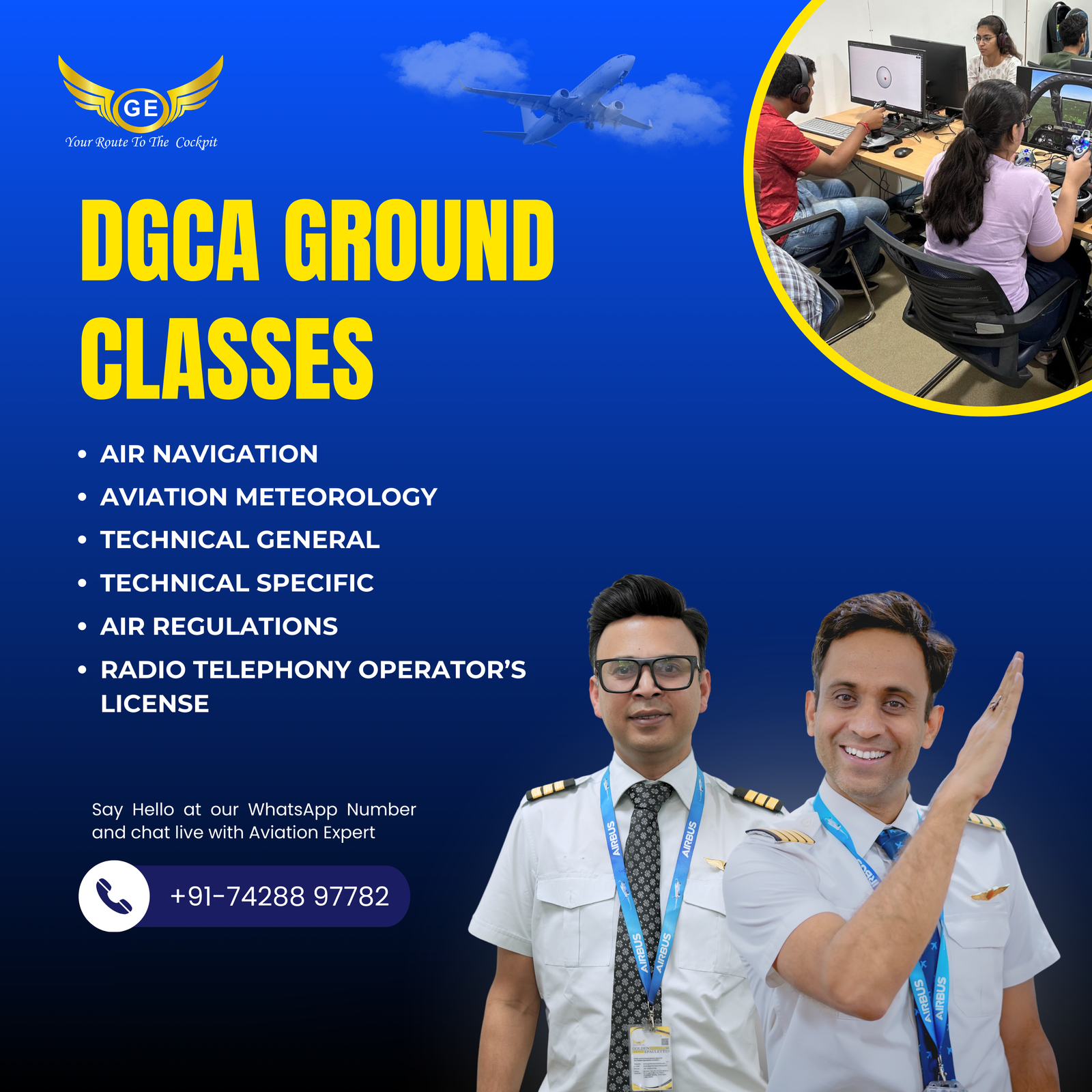

Air Navigation

Aviation Meteorology

Air Regulations

Technical General

RTR (A)

DGCA CPL Ground Class

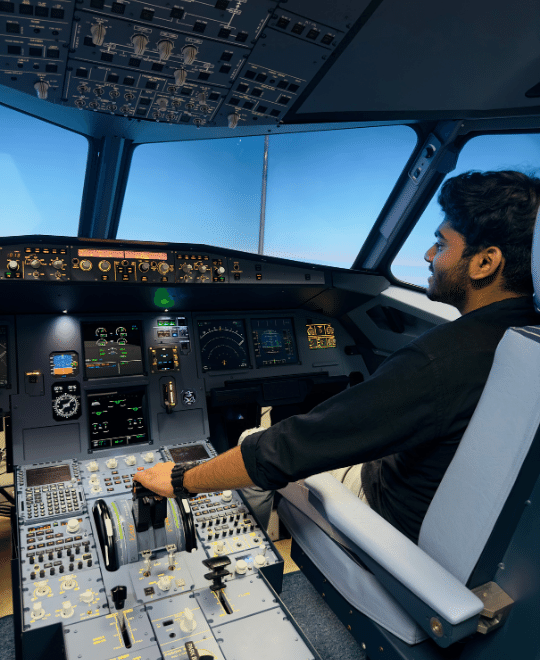

Commercial Pilot License Simulator

Airline Transport Pilot License (ATPL)

Airline Transport Pilot License

Aviation Meteorology

Air Navigation

Radio aids & Instruments

Airline Transport Pilot License Simulator

Cadet Pilot Program

Emirates Cadet Pilot Program

Indigo Cadet Pilot Program

Air Arabia Cadet Pilot Program

Spice Jet Cadet Pilot Program

Emirates Cadet Pilot Program

Qatar Airways Cadet Pilot Program

Indigo Cadet Pilot Program

CAE Cadet Pilot Program

FTA Cadet Pilot Program

SkyBorne Cadet Pilot Program

Insight Cadet Pilot Program

CAA Cadet Pilot Program

CAE Cadet Pilot Program

L-3 Cadet Pilot Program

Airline Preparatory Classes

Written exam preparation

CASS/COMPASS

Psychometry

Interview preparation

Flying Training

Flying Training in India

Aviation Academy Belgrade

Counselling

Career as a Pilot

Commercial Pilot License

Cadet pilot program

Indigo cadet pilot program

Flying Club/ Flying School

DGCA Computer Number

DGCA Medical

How to Become a Pilot

How to Arrange Finance Education Loan

CBSE Board Verification Certificate For 10th & 12th

Medical & Computer Number

DGCA Computer Number

Class 1 Medical for Airline Pilot

Class 2 Medical for Airline Pilot

Class 1 and 2 Medical for Airline Pilot

CBSE & ICSE X/XII Board Verification

How to Obtain a DGCA Computer Number for

Pilot Examinations

Schlorships

Civil Aviation Scholarship: Financial

Assistance for Aspirants in Aviation

Career

Civil Aviation Scholarship: Financial

Assistance for Aspirants in Aviation

Career

Pilot Training Scholarships -

Opportunities for Deserving Candidates

Pilot Loan Guide: Complete Information

for Aspiring Pilots in India

Axis Bank Pilot Loan Scheme: A Complete

Guide

Bank of Baroda Pilot Loan Scheme:

Eligibility, Loan Amount, Repayment

Options

IOB Pilot Loan Scheme - A Complete Guide

to Avail Financial Assistance for Pilot

Career

Information

How to become a Pilot

Comercial Pilot Licence

Airline Transport Pilot Licence

Airline Preparation

DGCA Medical

DGCA Computer Number

Cadet Pilot Program

Indigo Pilot Program

Simulator Classes

Type Rating

Pilot Career after 12th

Pilot Career for Graduate

Pilot Training Qualification

Pilot Training Cost

Pilot Career for Girls

Airport

Aviation Technology

International Aviation

Industries

Aviation Course

Pilot Training Aircraft

Airbus

A320

Boeing

737

Airbus

A330

Boeing

747

Boeing

777

Airbus

A350

Boeing

787

Embraer E-Jet

Bombardier CRJ Series

Sukhoi Superjet 100

ATR

72

De Havilland Dash 8

Airbus

A380

McDonnell Douglas MD-80

Home

About

Event & Opportunity

Pilot Career after 12th

Pilot Training for Girls

Aviation Course